Welcome to HOTH

BUSINESS LIVES ON QUALITY AND SERVICES.

Mud Mixing Equipment

20 m3

10 m3

Option #1: 10 m3 not divided.

Option #2: 5 m3 for mixing, 5 m3 for storage

8 m3, 6 m3

small type

Desanders

Desanders (viz. mud cleaners, mud recyclers) can remove the solid wastes - like sands, broken rocks - from the dirty mud. They work with the shale shakers and the hydrocyclones. Firstly the shaker separates away the large size solids and then the hydrocyclones the tiny ones. After the two-step separation, the remaining slurry is clean enough to be recycled for reuse in the underground drilling jobs.

250 m3/h - 100 m3/h

For slurry balance pipe jacking

200 m3/h - 50 m3/h

For horizontal directional drilling (HDD), rotary boring

250 m3/h, 200 m3/h

For dirty mud containing too many solid wastes.

Solid wastes are separated three times, firstly by the coarse screen, then by a pair of large hydrocyclones, and at last by a set of small hydrocyclones. That's how the mud gets cleaned enough.

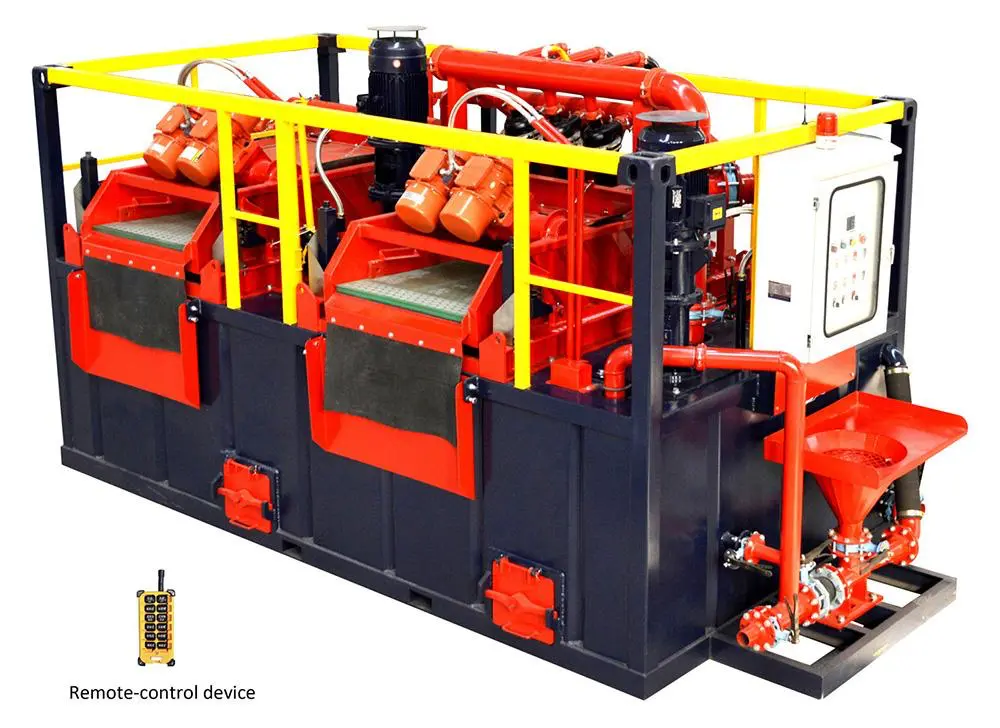

Mixing & cleaning (2-in-1)

One equipment performs two functions. This mud recycler is a combination of the mud mixing system and the desander. The structure is designed compact but make full use of the space. It is convinient to transport.

70 m3/h

For horizontal directional drilling (HDD), rotary boring.